What is Planogram Optimization?

Planogram optimization is the strategic process of organizing and adjusting in-store shelf layouts (planograms) to maximize sales, improve product visibility, and enhance the customer shopping experience.

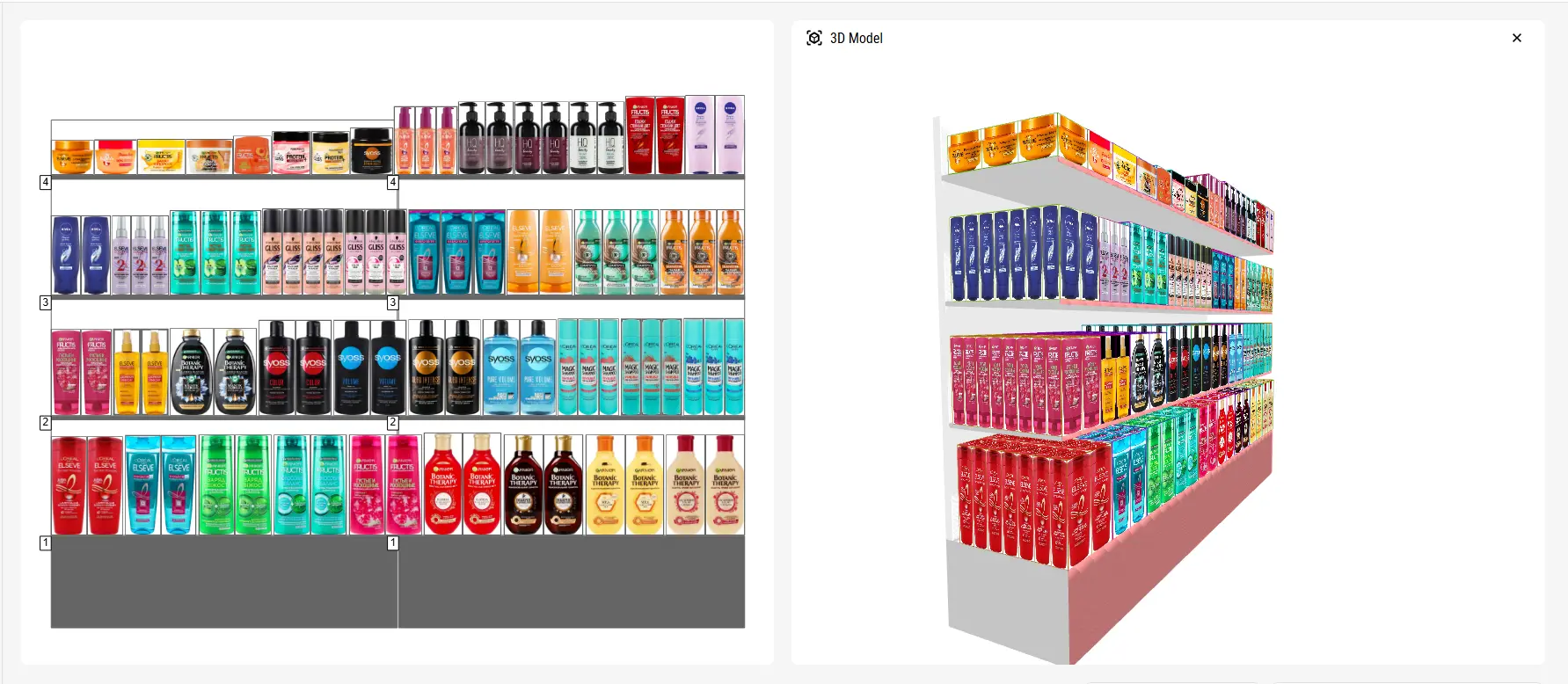

In practice, planogram optimization involves using data, analytics, and visual merchandising principles to ensure each product is placed in the right position, in the right quantity, and at the right time — all while aligning with your business goals.

Quick Example:

Before Optimization: A shelf layout is created manually, based on gut instinct or past experience, with minimal analysis of product performance.

After Optimization: The same shelf is redesigned using real-time sales data, ensuring top-performing SKUs are placed at eye level and complementary items are grouped effectively, boosting both visibility and sales.

Why Planogram Optimization Matters

Key Statistics:

- Planogram optimization can increase category sales by up to 12–20%.

- Retailers who implement planogram optimization tools report up to 30% reduction in out-of-stock (OOS) instances.

- Compliance with optimized planograms leads to 20–40% higher execution accuracy.

Who Benefits:

Retailers: Improve shelf productivity, reduce stockouts, and boost shopper engagement.

Brands (CPGs): Enhance product placement, support launches, and drive in-store promotions.

Supply Chain: Improve demand forecasting and shelf replenishment accuracy.

How Planogram Optimization Works (Step-by-Step)

1. Analyze Sales, Shopper Behavior & Layout Efficiency

Planogram optimization starts with deep data analysis. This means not only reviewing point-of-sale (POS) data, inventory metrics, and shopper behavior, but also evaluating the layout efficiency across your entire retail chain.

Using the PlanoHero analytics, retailers can:

- Monitor and compare key performance indicators (KPIs) across stores, categories, brands, and even individual products.

- Visualize data to identify underperforming layouts or hidden issues.

- Track the performance of both individual planograms and full store plans, including metrics such as turnover, number of receipts, sales, profit, and inventory levels.

- Drill down into featured product performance to assess the effectiveness of promotional placement.

The result? A data-backed foundation that turns raw metrics into actionable insights, helping you make smarter layout decisions and maximize shelf impact.

2. Align Space to Sales Ratio

Once you’ve identified top-performing products and weak spots, the next step is to align shelf space with real demand.

Using PlanoHero’s integrated reporting tools, you can:

- Track planogram-specific sales performance.

- Adjust shelf space allocation based on actual turnover and inventory movement.

- Reduce overstocking of slow movers and understocking of bestsellers.

This ensures your most profitable SKUs are prioritized, while low-performing items are managed more efficiently, all contributing to an optimized, revenue-driving shelf strategy.

3. Apply Visual Merchandising Rules

Ensure category blocking, brand blocking, and product adjacencies follow best practices. Group by color, size, or use case to create visual harmony.

4. Use AI Rules for Layouts & Automation

AI-powered tools like PlanoHero make planogramming faster, smarter, and far more scalable by allowing retailers to generate layouts based on dynamic rules. With just a few inputs, you can define detailed layout conditions including product groupings by category, brand, shelf, or price, as well as constraints like display height or number of facings. These rules can then be applied chain-wide, ensuring consistency and strategic alignment across all store locations.

Beyond rule creation, PlanoHero’s AI automatically fills empty shelf space with suitable products, maximizing every inch of shelf space while avoiding stockouts. The system helps retailers to improve execution speed but also saves valuable time and resources, transforming planogramming from a manual burden into an organized, data-driven process.

5. Human Review & Final Approval

Merchandising managers review generated planograms, make strategic adjustments, set execution deadlines, and push planograms to stores via digital platforms.

Common Challenges and How to Overcome Them

Resistance from Store Teams

Solution: Offer mobile tools (like PlanoHero's mobile app) for easy access and reporting, and involve store teams early in the rollout process.

Low Data Quality

Solution: Implement a central product database with accurate SKUs, stock levels, and sales data. Use PlanoHero Connector, an easy-to-use tool for uploading data to PlanoHero. Set a schedule for data updates. Use Connector tool and save time with an automated data upload process.

Poor Product Category Roles

Solution: Define clear category roles for the products and align layout strategies accordingly using analytics. Assign a clear role to each category based on shopper behavior and business goals. Common roles include:

Destination (draws customers in — e.g., diapers, coffee).

Routine (regularly purchased items — e.g., milk, bread).

Impulse (grab-and-go purchases — e.g,. candy, batteries).

Seasonal or Occasional (holiday items, BBQ supplies).

Once roles are assigned, use analytics to determine the best shelf space, product assortment, and placement strategy for each type. This makes your layout more intentional, shopper-friendly, and sales-driven.

How Technology Supports Planogram Optimization

- Centralizes product and sales data for accurate analysis

- Automates layout generation and compliance control

- Provides real-time feedback through photo validation

- Saves time on manual resets and updates

Solutions such as PlanoHero combine these capabilities, helping retailers move from manual planning to data-driven execution.

Tools & Technologies for Planogram Optimization

The right technology can turn a manual, inefficient process into a strategic advantage.

PlanoHero: AI-Powered Planogramming Tool

- Automates the creation, editing, and distribution of planograms.

- Offers realogram control with photo reporting.

- Includes analytics for products, categories, stores, and hot/cold zone detection.

- Mobile apps for store managers.

Planogram Optimization Best Practices

- Seasonal Adjustments: Shift layouts for holidays, back-to-school, summer sales, etc.

- Regional Customization: Adapt planograms to local preferences and store formats.

- Top SKU Positioning: Prioritize bestsellers in prime shelf locations.

- Realogram Validation: Use photo reports to verify execution in-store.

- Eye-Level Strategy: Follow the "eye-level is buy-level" principle to boost the product pickup rate.

SOCAR - PlanoHero Case Study

After digitizing its planogram process, one international retailer reduced reset time by 40% and improved on-shelf availability across 50+ stores.

The result: faster implementation and better merchandising control.

SOCAR, an international gas station chain operating 54 locations with retail markets across Ukraine, manages a wide assortment of over 10,000 SKUs. To support efficient merchandising and maintain consistency across its chain, SOCAR sought a solution to modernize and improve its planogramming process.

By implementing PlanoHero, SOCAR digitized its workflow and introduced centralized management of planograms. The platform enabled seamless communication between headquarters and store teams, incorporated real-time photo validation for planogram compliance, and eliminated the need for printed layouts. Additionally, merchandisers began using PlanoHero's mobile apps to quickly access and update planograms directly from the sales floor.

The result? Faster planogram creation, better execution control, and improved team and operational efficiency across the retail chain.

Key Takeaways:

-

Data-driven planogram optimization improves sales, accuracy, and shopper experience.

-

Regular updates and visual audits are essential to maintain performance.

-

Technology now allows real-time collaboration between HQ and store teams.

If you’re looking to modernize your shelf management process, exploring planogram automation software like PlanoHero can be a strong next step. See PlanoHero pricing

FAQ: Planogram Optimization Questions Answered

How often should planograms be optimized?

Every 3–6 months, or more frequently for fast-moving categories or seasonal adjustments.

Who should own the optimization process?

Typically, the Category Manager or Merchandising Team, with inputs from analytics and marketing.

What’s the ROI of planogram optimization?

Depending on the category and execution quality, you can expect 5–20%+ sales uplift, reduced OOS, and higher planogram compliance rates.

Can planogram optimization be automated?

Yes, advanced tools use AI and data integration to automatically generate layouts and balance facings, saving significant manual time.

How can retailers measure optimization results?

By tracking key metrics such as sales uplift, turnover rate, and planogram compliance accuracy.

Final Thoughts

Planogram optimization isn’t a one-time task — it’s a continuous process that combines data, technology, and visual strategy. With the right tools like PlanoHero and a commitment to ongoing improvement, your shelves can become smarter, more efficient, and more profitable.

Ready to see how technology can simplify planogram optimization? Explore available tools or start with a free demo of PlanoHero to experience how data and automation can transform your shelf strategy.

Looking for a service to create planograms?

Try a free demo version of PlanoHero