Mitigate Retail Out-Of-Stock with PlanoHero Planogram Service

Planograms and Out-Of-Stock Control

How to Deal with Out-Of-Stock in a Store?

The non-availability of products on the shelves and in the warehouse disappoints customers, leads to lost sales, and costs retailers a lot of money.

What is Out-Of-Stock?

Out-of-stock means the absence of products or their shortage. In simple terms, the product is unavailable to the customer who wants to buy it. In retail stores, this is usually a situation where there is not enough merchandise on the shelves or a certain SKU, such as a size or color, that the customer needs. The only positive thing about out-of-stock is that it can also mean that the product had high sales and ran out quickly. But that's where the good news ends. Then the problems begin.

When a product is out of stock, it has many negative consequences for retailers. Out-of-stock reduces sales. When a store does not have the right product, a customer may leave without buying. This means lost sales, decreased customer loyalty, or even a reputational loss and an outflow of regular customers. To cope with out-of-stock, retailers must either re-order goods or transport them from another warehouse. Due to the urgency, paying more for procurement, delivery, and storage is sometimes necessary.

That's why it's essential for retailers to detect out-of-stock in a store in time and discover the reason for the shortage.

Planograms and Out-Of-Stock Control

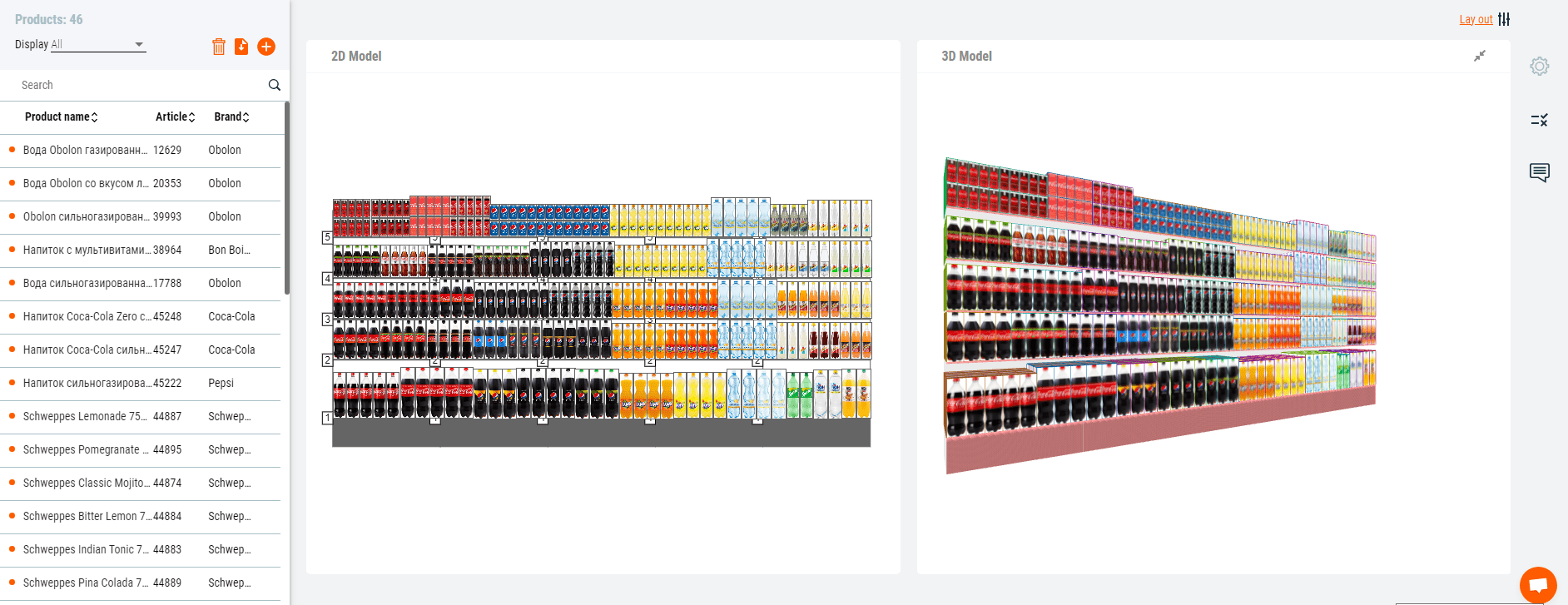

Retailers use planograms to create attractive layouts. They are also a great tool for controlling stock on the shelves. Working with the PlanoHero service, retailers can not only track the effectiveness of the layout, but also receive information about out-of-stock.

PlanoHero is a service for the planogramming automation process in store chains. The tool helps retailers to organize the merchandising process in the store in such a way as to ensure an attractive layout and track any problems with the product.

PlanoHero service features:

- building a retail store plan and fixtures;

- creation of planograms with different layout settings;

- control over the planogram execution with the help of photo reports;

- tracking assortment issues;

- analyze the layout, sales, and customer behavior.

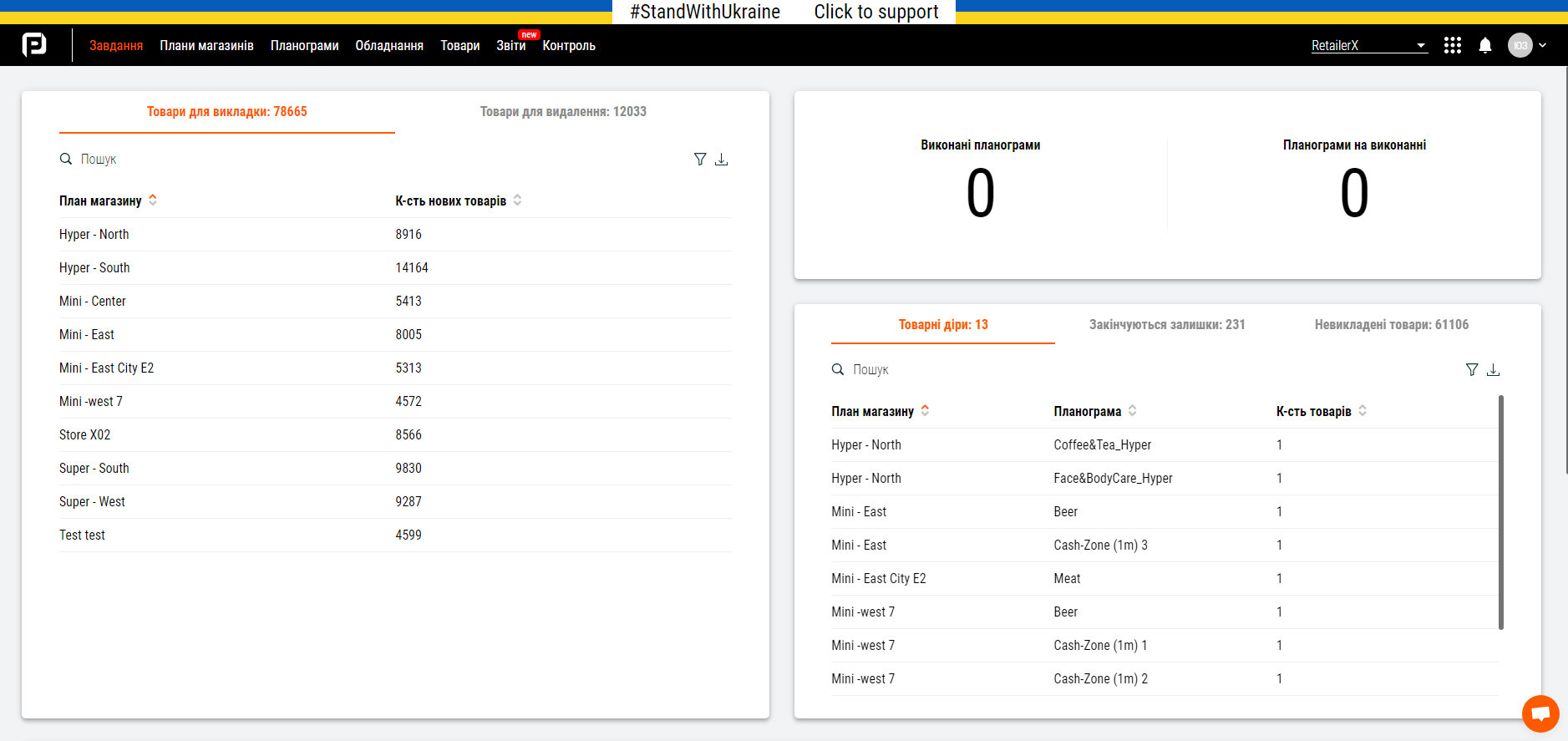

With PlanoHero, the merchandiser receives real-time information about assortment issues: out-of-stock on planograms, products that will be enough for only one day. We call out-of-stock products that are displayed on planograms but are not available in the store.

Thanks to the service, the planogramming department can track changes in the assortment:

— new products that need to be displayed. The PlanoHero service notifies about products that are not yet on the planograms;

— products that should be removed from the planograms.

What Causes Out-Of-Stock in a Store?

- Incorrect planning and wrong inventory forecasts result in fewer goods in the store than expected.

- A sharp increase in demand for a specific item.

- Lack of control over processes in the store.

- Suppliers' delays.

Empty shelf space can occur due to an improperly formed order, logistics problems, or the human factor – the responsible manager forgot to take the goods out of the warehouse and place them on the shelf

In the long run, product shortages can become a severe issue. The lack of goods can reduce profit margins. If a customer comes to buy a product and it is out of stock, the retailer loses profit from the lost sale. Reputation among customers also suffers. And your competitors can steal your customers.

How to Deal with Out-Of-Stock in a Store?

To prevent out-of-stock, retailers need to optimize all planning, ordering, and merchandising processes. In situations where the shortage is beyond the retailer's control, it is essential to reduce costs and customer dissatisfaction. For example, offer an alternative product or find another supplier. Sometimes, a customer is ready to buy a substitute product if it is unavailable.

The use of planograms helps to ensure a constant supply of goods. By analyzing sales, the retailer understands in how many days a particular product will be sold out if sales indicators are the same as the previous ones. The algorithms of the PlanoHero service calculate the shelf stock and show the amount of remaining goods in days and pieces.

Well-designed planograms ensure that any replenishment of shelves will not occur by chance. The merchandiser creates a planogram, sends it to the store, and controls the execution of the layout.

Also, using planograms ensures that the products have the right shelf space. For example, if the demand for a particular product suddenly increases, the merchandiser can use the planogram to give this product more faces and place it in a better place on the shelf so that customers can easily find it.

In addition, with the help of sales analysis, you can determine which products are selling slowly and decide to remove these products from the shelves. This will make room for products that generate more sales.

Conclusion

Out-of-stock is an unpleasant experience for both retailers and customers. Retailers must ensure enough stock on the shelves and understand how to manage shelf space to avoid “product holes properly.”

The PlanoHero service has a separate block for working with out-of-stock, with data updated every day. Thanks to the service, the merchandising department receives information about product shortages and can effectively control shelf stock to avoid lost sales.

Looking for a service to create planograms?

Try a free demo version of PlanoHero